A New Aircraft for Urban Air Mobility

Marc Ausman

Expanding the vision for next-gen aerial transportation

The case for UAM is a strong one. The UAM concept envisions using next-generation aircraft to move cargo and people directly into and out of urban, suburban, and even rural areas using non-traditional airports. Electric propulsion enables new types of aircraft designs that now make it commercially feasible to fly missions that aircraft typically haven’t flown in the past.

Having many smaller airports rather than a single big one provides for a much more efficient flow of cargo and people. We can now consider operating from unused open areas, piers, helipads, dirt roads, and fields rather than driving to an airport and fighting the delays there.

Most of the interest around UAM has focused on future electric Vertical Takeoff and Landing (eVTOL) aircraft, which take off vertically like a helicopter then transition to wing-born fight like an airplane. But when we look at today’s transportation system, we see that there are many types of vehicles that each meet a specific need.

Our team at Airflow.aero recognized this. We also appreciated the risky and expensive efforts to design, test, certify, and manufacture eVTOL aircraft, having just finished a successful development and test program with the Airbus Vahana technology demonstrator. We were keenly aware of the challenges and compromises inherent in current eVTOL designs and asked ourselves if there were alternate ways to address the UAM market.

It turns out there is an alternative that is simpler, with lower development cost and risk and is less than half the operating cost of an eVTOL. We propose that electric Short Takeoff and Landing (eSTOL — pronounced “e-stole”) aircraft are also suitable for UAM missions.

We started Airflow.aero to develop and commercialize eSTOL technology and offer transportation services that simply don’t exist with today’s commercial aircraft.

A new revolution in aviation

While aerospace technology continues its evolutionary path, there have been some significant revolutionary inflection points in aircraft development. New propulsion technology has been at the center of each revolution.

The first revolution occurred when the Wright brothers used an aluminum block engine at a time when others were using cast iron and even steam engines. That made the aircraft just light enough to fly. The rest is history.

The next revolution occurred when metallurgists and other brilliant engineers developed a commercially-viable turbine engine that embarked humankind on the jet age. The capabilities enabled by jet aircraft and the market for travel they created shrunk the world. It would be an understatement to say this development changed the course of history.

We are now standing at the beginning of the third revolution in aviation. This time the enabler is electric propulsion, made up of powerful electric motors, batteries that are just now reaching a useful energy density, and efficient motor controllers. Much like the Internet in 1994, the new capabilities will allow us to do things that were previously unheard of.

Interestingly, electric propulsion is best suited for aircraft at the opposite end of the performance spectrum from jet aircraft. Turbine engines are well suited for fast, long-range aircraft, and electric motors are best for relatively slow, short-range aircraft. This complementary relationship between old and new technologies means new electric aircraft expand the capabilities and benefits of aviation rather than cannibalize them.

“new electric aircraft expand the benefits of aviation rather than cannibalize them”

Electric motors are truly amazing because they are not merely drop-in replacements for piston or turbine engines. Electric motors, because they scale down in size very nicely and decouple power generation from thrust generation, allow aircraft designers the opportunity to explore many new designs that are not practical with traditional internal combustion engines.

Many types of aircraft

The focus of much of the UAM industry so far has been on eVTOL, but several other configurations can also benefit from electric propulsion. The basic operational types are:

STOL ( Short Takeoff and Landing) These are fixed-wing aircraft designed to take off and land on very short runways, fields, roads, beaches, and other rugged terrain.

VTOL (Vertical Takeoff and Landing) These are aircraft that take off vertically like a helicopter, then transition to flying like an airplane, then transition back to land like a helicopter.

CTOL (Conventional Takeoff and Landing) These are fixed-wing aircraft designed to take off and land on long paved runways typically found at conventional airports.

Each will have a place in the future and a role in the UAM market. We believe eSTOL aircraft are well suited for the UAM mission and offer meaningful benefits over other options. In the following paragraphs we explain why.

Setting a baseline for comparison

eSTOL aircraft offer a unique combination of short-field versatility combined with technical simplicity.

For the sake of comparison, we’ll focus on eSTOL and eVTOL aircraft with the following characteristics:

- All electric or hybrid-electric propulsion systems (note that cost and range figures discussed below apply to all-electric aircraft)

- A single pilot

- A payload of two passengers or 500 lbs of cargo

Before we dig into specific points of the aircraft, let’s address one of the biggest assumptions people make when considering UAM: an eVTOL aircraft can land vertically, whereas an eSTOL aircraft needs more room for takeoff and landing. The greater area needed by eSTOL aircraft for takeoff and landing incorrectly leads one to believe that only eVTOL aircraft can perform the UAM mission.

“The greater area needed by eSTOL aircraft for takeoff and landing incorrectly leads one to believe that only eVTOL aircraft can perform the UAM mission.”

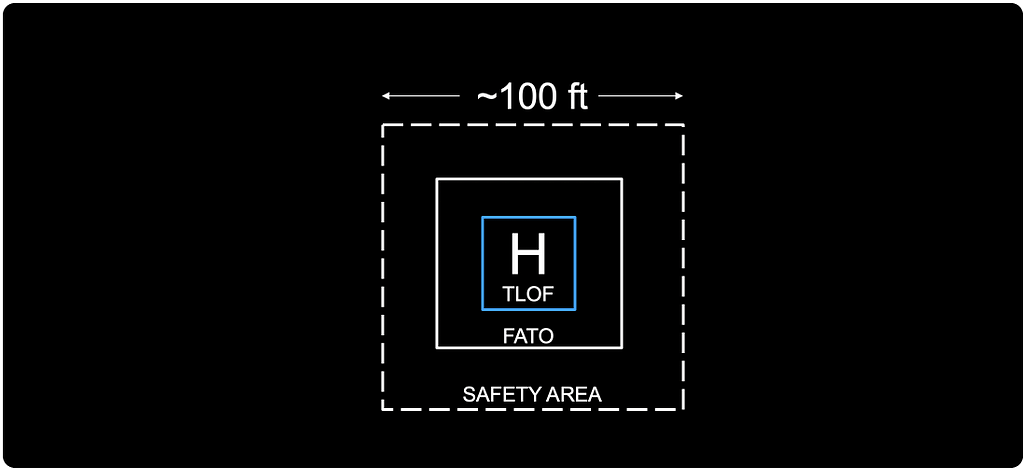

First, let’s look at the space requirements for a helipad. The FAA provides guidance for the design of heliports in a document called AC 150/5390–2C (an Advisory Circular (AC) offers advisory guidelines and does not promulgate laws or regulations). This AC describes the minimum dimensions for a helipad as well as surrounding safety areas. For a typical eVTOL, a helipad, and its surrounding safety area need to be about 100 ft in diameter or a 100 ft square.

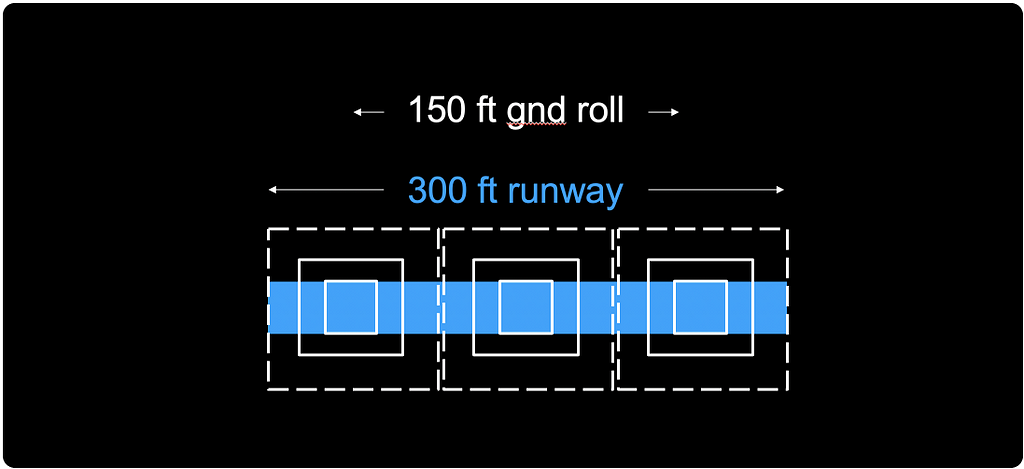

An eSTOL aircraft of the size described above needs about 150 feet ground roll for takeoff and landing, which translates into about a 300-foot runway when accounting for a safety margin.

Therefore, an eSTOL aircraft can take off and land in an area the length of three helipads.

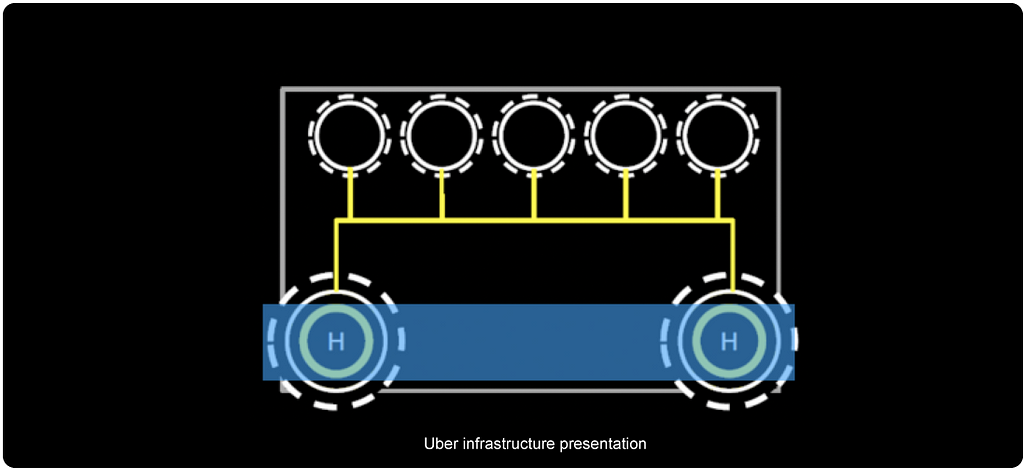

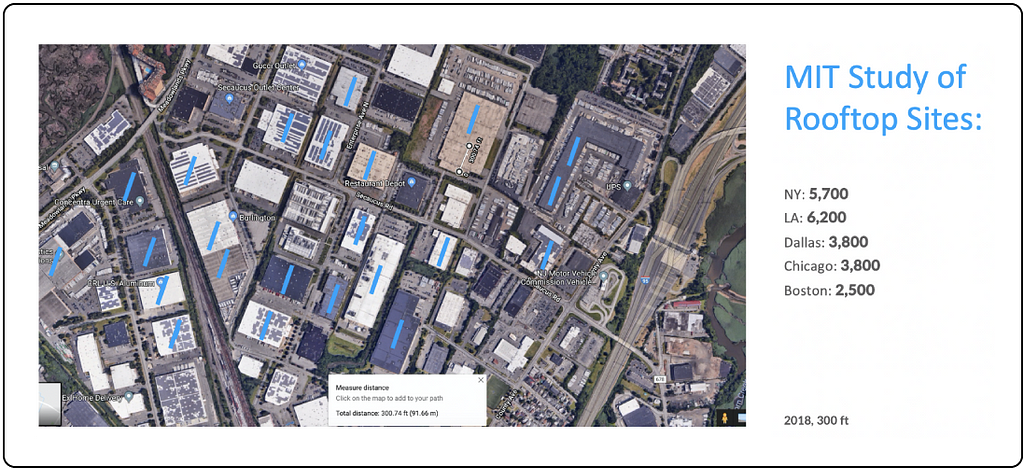

Shown below is an example of a helipad configuration that could handle both eVTOL and eSTOL aircraft. One can see two helipads, a runway in blue, and numerous parking spots.

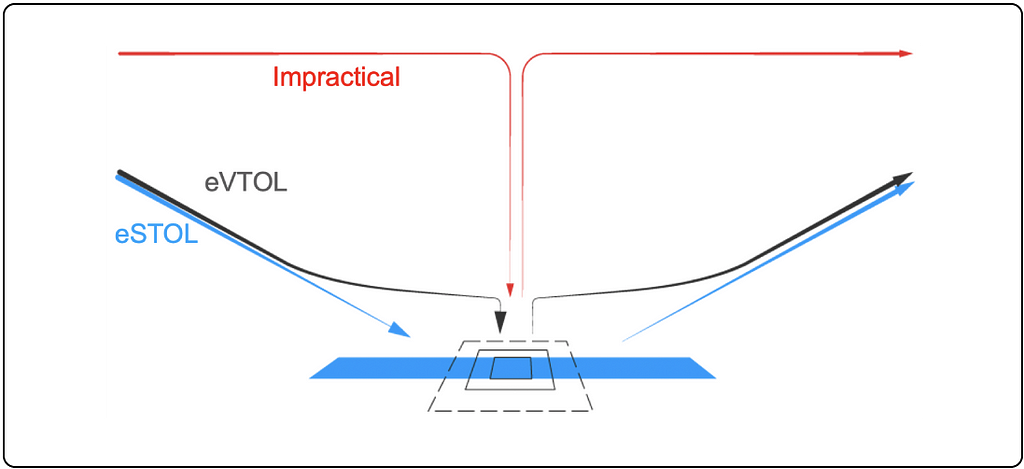

Next, we’ll look at approach and departure paths from a helipad. The AC goes on to describe required obstacle clearance zones along the approach and departure paths out at least a mile from the helipad. The AC explains that obstacles must be clear above an imaginary 7-degree slope extending outward from the helipad along the approach and departure path.

For comparison, a CTOL aircraft nominally flies an approach at a 3-degree slope (called a glideslope). An eSTOL aircraft can fly a 7 degree or steeper glideslope, which is above the minimum required for helicopters and presumably eVTOLs. Therefore, any needed obstacle clearances that are necessary for eVTOL can be met by eSTOL aircraft as well.

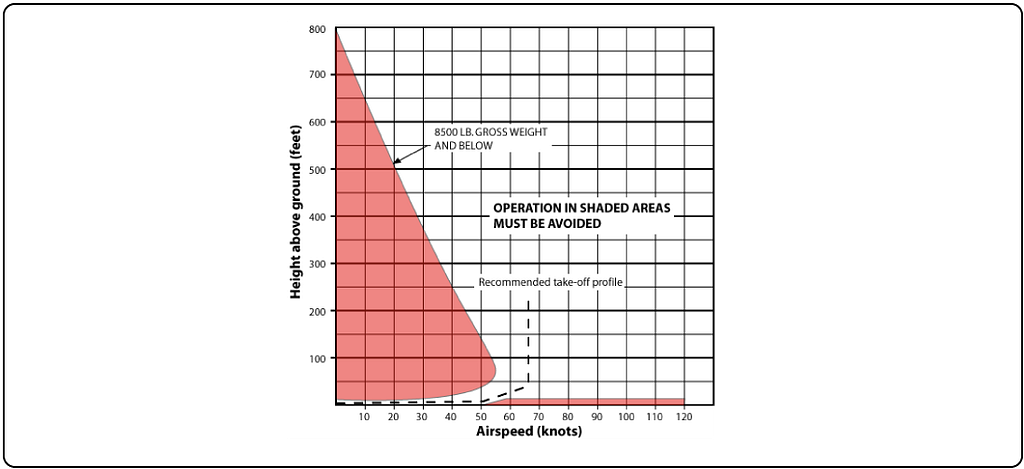

If you’ve never flown a helicopter, it’s easy to think that helicopters fly vertically from the helipad straight up to altitude. This is almost never the case. Helicopters fly forward after takeoff, just like an airplane, to build up energy so they can land safely in case of an emergency. As you can see in the height–velocity diagram below, there is a small safe zone where helicopters can fly after takeoff until they can build speed — climbing vertically after takeoff is strictly prohibited.

One of the benefits of the multi-rotor eVTOL design is that the motor redundancy precludes the need for autorotation capability. If a motor fails, the other motors can compensate. In theory, an eVTOL aircraft has a much broader area in which to fly on the H/V diagram.

In reality, an eVTOL aircraft must transition as quickly as possible from vertical flight mode to winged (horizontal) flight mode, due to the tremendous energy required for vertical flight and the limited energy storage capacity of batteries. Every minute in hover costs about 5 minutes, or 10 miles, of cruise flight. Assuming an eVTOL aircraft has a range of about 60 miles, a 20-mile reduction (10 miles equivalent of hover on each end of the flight) means a 33% reduction in an already limited range capability. It is very possible that eVTOLs will have strict time limits on vertical flight mode due to thermal concerns.

Because eVTOL aircraft must spend maximum time flying on the wing, it means both eVTOL and eSTOL aircraft will have a similar approach and departure path, as shown in the diagram below. So, in general, if a landing site can support three helipads, it can support both eSTOL and eVTOL aircraft.

Finally, we’ll look at additional locations where an eSTOL aircraft can land. eSTOL aircraft can land in urban areas as well as rural areas outside the urban core. To better understand the opportunity for landing sites for eSTOL aircraft we did two things. First, we performed a quick analysis to understand how many industrial rooftops are, in theory, large enough to accommodate a 300-foot runway. The image below shows that the majority of rooftops in a random industrial park can meet these criteria (the blue lines are runways aligned with the prevailing wind). Second, we look at an MIT study from 2018 that analyzed the number of buildings with a footprint large enough to support a runway on the rooftop. The chart to its right shows the number of 300-foot runways in major metropolitan areas.

If we assume only 1% of these are viable operating sites, then we’re left with anywhere from 25 to 62 locations per city, plus another (maybe) 50–100 sites per city at ground level. Such a network can support hundreds of eSTOL aircraft and thousands of operations per day per city.

Outside of urban areas, eSTOL aircraft can land in many areas that traditional commercial aircraft don’t serve. These include roads, fields, piers, parks, beaches, parking lots, and rooftops with appropriate infrastructure. If a dedicated runway is needed, then a 50 x 300 ft strip of asphalt can be built.

The case for eSTOL aircraft

Now that we’ve talked about the operating environment let’s compare eSTOL and eVTOL aircraft across several metrics. While there are many, let’s focus on the items below. For use cases where at least 300 feet of runway is available, a eSTOL aircraft offers the following benefits when compared with eVTOL aircraft:

- Lower program risk

- Lower operating costs

- Lower certification cost & risk

- Lower development cost

- Lower noise

Let’s discuss each one.

Lower program risk

The program risk is a subjective measure to understand the risk of the overall development program. The chart below describes items that contribute to program risk. Lower risk items lower the overall risk of the program and reduce the chance of cost overruns and time delays.

By these metrics, an eSTOL program represents a lower risk than an eVTOL program.

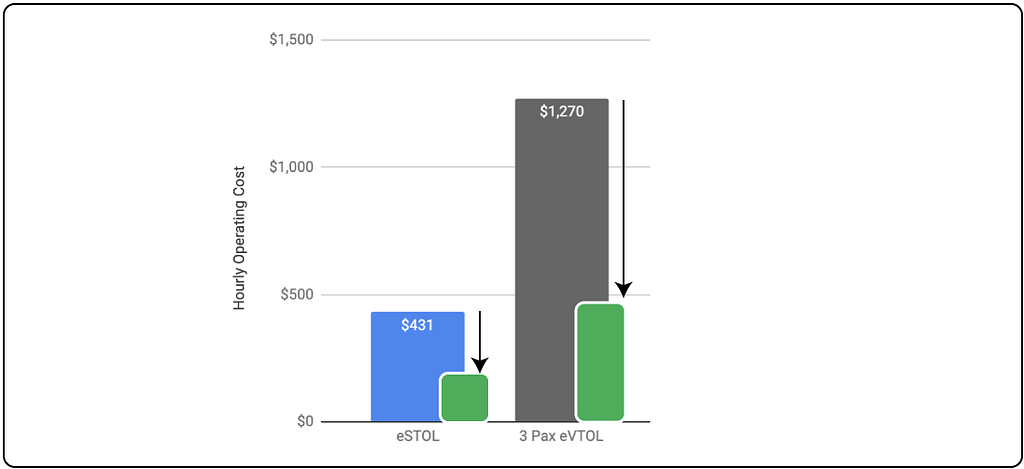

Lower operating cost

We developed a bottoms-up cost comparison model based on assumptions from numerous industry sources as well as our own experience. The model is based on the methodology used by Conklin & de Decker’s Aircraft Cost Evaluator (ACE) to build up both fixed and variable costs. The helicopter data come from a 2019 ACE report, and comparable items are included for the electric aircraft. The costs include, but are not limited to, electricity/fuel, battery/turbine accruals, pilot expenses, depreciation, scheduled & unscheduled maintenance, insurance, pilot training, and navigation data.

The chart below shows the estimated hourly operating costs at entry into service (EIS). The EIS timeframe assumes 600 hours annual utilization, $625 per kWh at the pack level, and 210 Wh/kg energy density for batteries. The eSTOL and eVTOL costs are for all-electric aircraft.

From this chart, we can see that eVTOL aircraft have a similar hourly operating cost to small turbine helicopters, and eSTOL aircraft have significantly lower operating costs.

The main cost drivers for the electric aircraft are:

- Depreciation (52%) — using a 10-year straight-line depreciation schedule, per C & de D (same as that used on the helicopters).

- Battery accruals (25%) — this is the cost to replace batteries.

- Insurance (12%) — includes hull and liability coverage.

- Pilot (4%) — at $50/flight hour including benefits.

The good news is that the cost of maintenance and electricity is negligible. The other good news is that both types of electric aircraft have a path to significant future cost reductions. The estimated decrease in operating cost over an arbitrary period, say ten years, is shown below.

The drivers for cost reduction over time include:

- Increased utilization to 1500 flight hours annually

- Better & cheaper batteries

- Lower insurance cost

- Increased motor and propeller time between overhaul (TBO)

- Increased maintenance intervals and a shift from life-limited parts to on-condition (or predictive) replacement.

- Slightly lower airframe price.

Because of their relative simplicity and gentler use of batteries, eSTOL aircraft have a significantly lower operating cost than eVTOL.

Lower certification risk

We believe that certification of an eSTOL aircraft is significantly more straightforward than an eVTOL aircraft. From a certification standpoint, eSTOL aircraft are conventional fixed-wing aircraft with just a bit of new magic to enable new capabilities. We expect to use Part 23 as the certification basis for the aircraft.

On the other hand, almost everything on an eVTOL is new magic. For example, eVTOL aircraft require a fly-by-wire system, but such a system has never been certified on Part 23 aircraft before. And there is significant added complexity because the motors and control surfaces are used for different purposes during different phases of flight. While technically feasible, it adds meaningful risk and cost to the certification program.

Furthermore, US and European regulators have not agreed on a standard for eVTOL certification, nor does it appear they are converging on one. The European Union Aviation Safety Agency (EASA) has published stringent specifications for eVTOLs flying in urban areas, essentially holding those small aircraft to large aircraft levels of safety. Such a requirement is unprecedented for small aircraft. The FAA in the US has not published any formal specifications and is handling each program on a case by case basis. Such regulations, or lack thereof, add meaningful cost and risk to any development program and may force OEMs to develop to two different standards.

eSTOL aircraft certified to straightforward Part 23 standards compare favorably to uncertain and challenging eVTOL standards.

Lower development cost

We believe that eSTOL aircraft are much lower cost to develop and represent a much more efficient use of capital than eVTOL aircraft, due to the reasons mentioned above, recapped here:

- Technical simplicity and elegance

- Ability to use standard Part 23 certification means of compliance

It is important to note that no eVTOL program has been certified to date, so there is no historical data or industry knowledge on which to base an estimate. Each company makes decisions on how it spends money and accepts risk, so the numbers we propose are very rough estimates and can vary widely between companies. Fortunately, eVTOL certification costs will go down over time as regulators and industry become more knowledgeable and gain more field experience.

We expect an eSTOL aircraft can be developed and brought to market for about $200M, whereas an eVTOL requires about $700M. The absolute numbers are less important than the large difference between them.

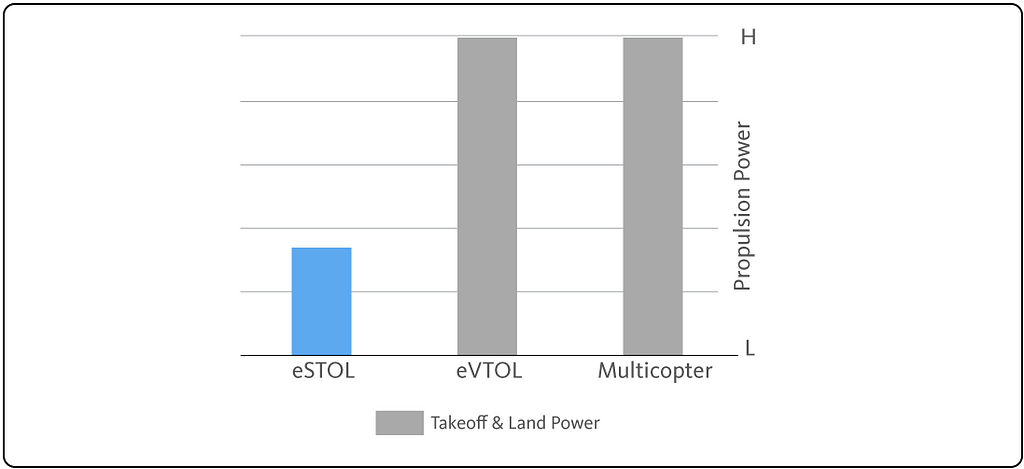

Lower noise

The industry expects both eSTOL and eVTOL aircraft to be very quiet in cruise at about 1,000 to 2,000 feet above ground level. The industry recognizes that low noise levels are essential to community acceptance of these new aircraft. Also crucial to the local community is the noise level during takeoff and landing. To make a broad market assessment, we are using motor power levels as a proxy for noise. Higher power during takeoff and landing generates higher noise levels. Lower power during takeoff and landing generates lower noise levels.

eSTOL aircraft use about two times cruise power for takeoff and less than that for landing. eVTOL aircraft use about four to six times cruise power for both takeoff and landing.

Conclusion

We are at the beginning of a new and exciting chapter in aviation and transportation enabled by electric propulsion. There are many ways to implement electric propulsion, and each has its own set of tradeoffs. In this paper, we’ve highlighted the benefits of eSTOL aircraft to show that both eSTOL and eVTOL aircraft are suitable for UAM missions.

Discover more from sUAS News

Subscribe to get the latest posts sent to your email.